Wholesale Price China Automatic Steel Bar Bending Machine - Manual metal bar bending machine – Jindi

Wholesale Price China Automatic Steel Bar Bending Machine - Manual metal bar bending machine – Jindi Detail:

GW40/GW50 REBAR BENDING MACHINE has reasonable design, simple structure and can bend steel rod diameter to any required shape applying to bridge, tunnel and many construction projects.

Main Features 1. Simple operation, safe and durable, high quality copper wire motor, guarantee a more stable performance. 2.Fully enclosed gearbox lubrication, worm gear and worm drive, with speed adjustable gear, strong bending strength, not rebound. 3.ultra-high hardened accessories, adjustable baffle which guarantee a longer service life. 4.Machine surface adopts plastic-spray treatment; Accessories like long strips and disc are solid, forged, and chrome plated, so they are beautiful and generous. 5. Specially use thickened steel plate, high rigid disc and bar iron, high power medium speed national standard high quality electronic motor, guarantee a more stable performance.

| Model | GW40 | GW50 |

| Voltage | 3-380V 50HZ | 3-380V 50HZ |

| Motor Power | 3.0KW | 4.0KW |

| Motor Speed | 1440r/min | 1440r/min |

| Rebar Bending Diameter Scope |

Common Carbon Steel≤40mm | Common Carbon Steel≤50mm |

| Grade Ⅲ Deformed Bar≤32mm | Grade Ⅲ Deformed Bar≤40mm | |

| Working Plate Diameter | 350mm | 400mm |

| Spindle Speed | 7r (14r)/min | 7r (14r)/min |

| Weight | 345kg±5kg | 380kg±5kg |

| Dimension | 930*770*740mm | 1040*800*770mm |

Spare Parts:

| Spare Parts | Spectification(mm) | Main Function |

| Blocking Rack | Ø54mmØ43mm | Adjust bending time gap according todifferent diameter rebar |

| Eccentric SleeveColumn Sleeve | Eccentric sleeve Ø108(Ø118)mmColumn sleeve 1 Ø96mmColumn sleeve 2 Ø77mm

Column sleeve 3 Ø63mm |

Adjust rebar gap when bending differentdiameter rebar |

| Central Column/Blocking Column | Central Column Ø65(Ø30)mmBlocking Column 1 Ø43(Ø54)mmBlocking Column 2 Ø26 mm

Blocking Column 3 Ø30 mm |

Ward rebar when bending rebar |

CHARACTERISTICS OF REBAR BENDING MACHINE

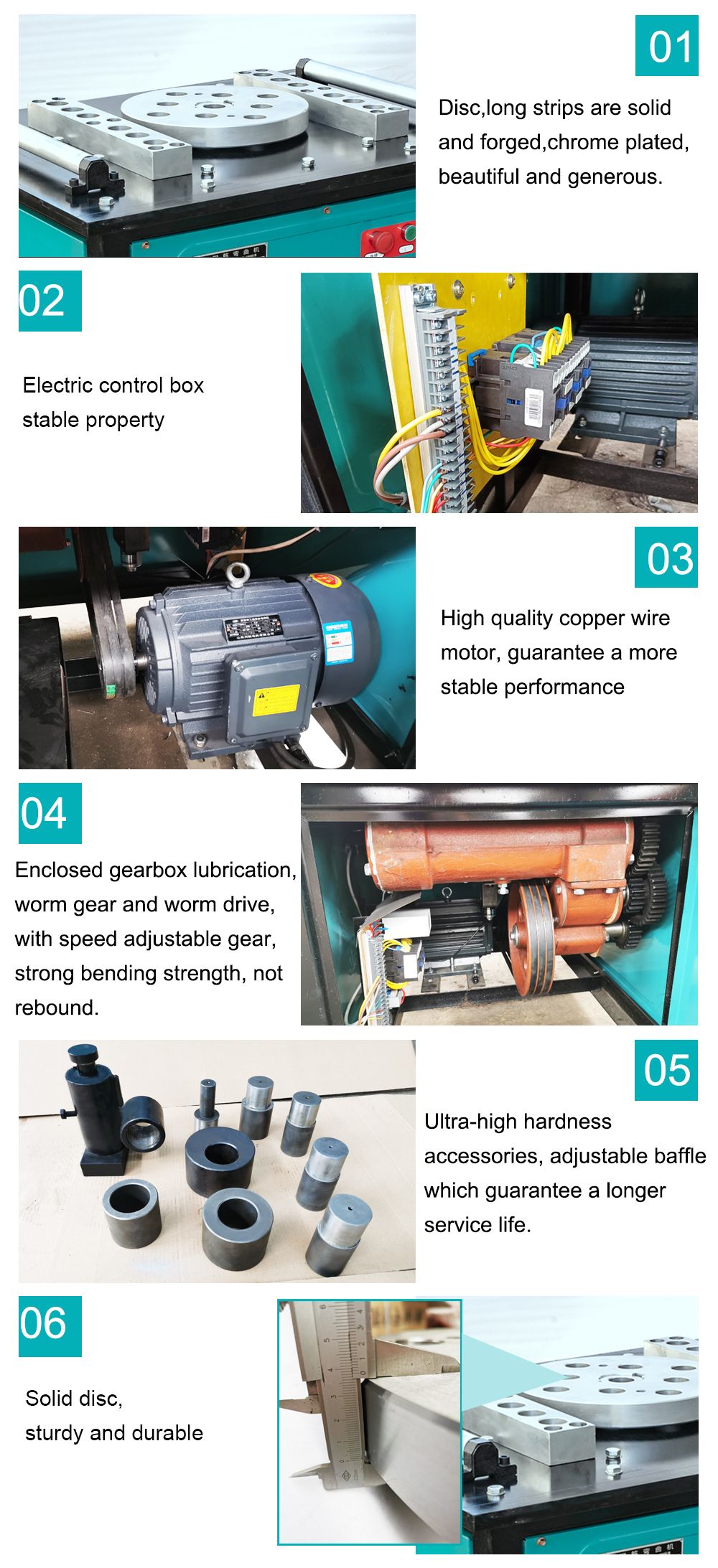

1.Disc,long strips are solid and forged,chrome plated,beautiful and generous.

2. Electric control box

3.High quality copper wire. motor,guarantee a more stable performance

4.Enclosed gearbox lubrication, worm gear and worm drive, with speed djustable gear, strong bending strength, not rebound.

5. Ultra-high hardness accessories, adjustable baffle which guarantee a longer service life.

6.Solid disc, strudy and durable

Our Services & Strength

We are experienced factory of rebar bending machine, rebar cutting machine, rebar thread rolling machine, we accept custom of machine logo, colour, motor parameter, thread data, etc.

FAQ:

1. Can the motor voltage be changed?

Yes, the machine standard voltage is 3-380V-50HZ, we also can change motor to 220V, 415V, or 440V.

2. What are the consumable spare parts?

Commonly used spare parts are blocking column, eccentric sleeve, V-belt. We have them in stock, you can buy it easily.

3. What is the warranty of your machine?

Machine warranty is 6 months. During the guarantee period, if any quality problems occur, we will provide the related spare parts(consumable spare parts not included) free of charge.

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for Wholesale Price China Automatic Steel Bar Bending Machine - Manual metal bar bending machine – Jindi , The product will supply to all over the world, such as: Jeddah, Honduras, Romania, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!