High Quality Rebar Sleeve - rebar upsetting machine for construction – Jindi

High Quality Rebar Sleeve - rebar upsetting machine for construction – Jindi Detail:

Rebar Forging Machine is a type of equipment used for enlarging ends of rebars.

16-32 model Double Cylinder Rebar Upsetting Forging Machine

Machine Function

16-32 model Double Cylinder Rebar Upsetting Forging machine is mainly used for upsetting 16-32 diameter rebar, increase the diameter of rebar, make rebar end enlarged, in order to make the effective section is larger than the original steel.

Such as for 25mm rebar, after upsetting, it is become 28mm.

Then you can use rebar thread rolling machine or rebar thread cutting machine to get rebar threads, connect with rebar.

Machine Advantages

After upsetting by 16-32 model Double Cylinder Rebar Upsetting Forging machine, its tensile strength is larger than original rebar itself. This machine is applicable to the reinforcement connection of national key projects with high requirements such as bridges and subways, and is not affected by environmental factors.

Machine Parameters

|

Model |

16-32 |

16-40 |

|

Processing Range |

Φ16 – Φ32mm |

Φ16 – Φ40mm |

|

Upsetting Length |

3-5cm |

3-5cm |

|

Motor Power |

7.5KW |

11KW |

|

Rated Voltage |

3 – 380V – 50HZ or others |

3 – 380V – 50HZ or others |

|

Working Efficiency |

3-5 seconds / piece |

3-5 seconds / piece |

|

Capacity of Tank |

115L |

165L |

|

Oil Pump Flow |

15L/min |

15L/min |

|

Hydraulic Oil Pump |

31.5Mpa (10MCY 14-1B) |

31.5Mpa (10MCY 14-1B) |

|

Hydraulic Oil |

68# Antiwear |

68# Antiwear |

|

Working Stroke of Cylinder |

150mm |

150mm |

|

Weight |

1000KG |

1300KG |

|

Dimension |

1250*850*1650mm |

1340*990*1800mm |

Machine Spare Parts

For one size rebar, need one mould, one set mould has 2 pieces.

FAQ

Q1:What is the machine motor ?

A1:The machine motor is 3-380V-50HZ. but we also change it to 3-220V-60HZ, 3-415V-50HZ, 3-440V-60HZ, etc.

Q1: What is the rebar diameter after upsetting?

A1: After upsetting, the rebar diameter will become bigger. For instance, after upsetting the 25mm rebar will become 28mm. But if you have other special requirement, we also can customize mould for you. Q1: What is the machine spare parts?

A1: The machine spare parts is mould. each size rebar needs one mould.

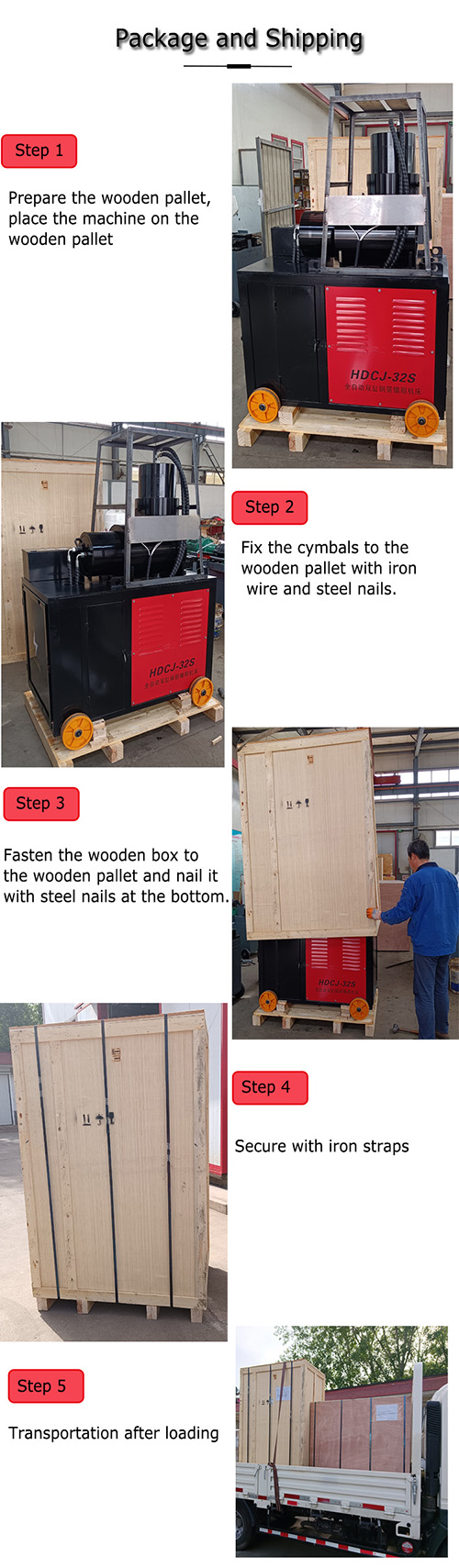

Package and Shipping

The machine is packed with plywood case.

Customer Photos

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for High Quality Rebar Sleeve - rebar upsetting machine for construction – Jindi , The product will supply to all over the world, such as: Egypt, Marseille, Bandung, Due to the stability of our products, timely supply and our sincere service, we are able to sell our products not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!