China OEM Thread Rolling Machine Roller Installation - electric fully automatic rebar thread rolling – Jindi

China OEM Thread Rolling Machine Roller Installation - electric fully automatic rebar thread rolling – Jindi Detail:

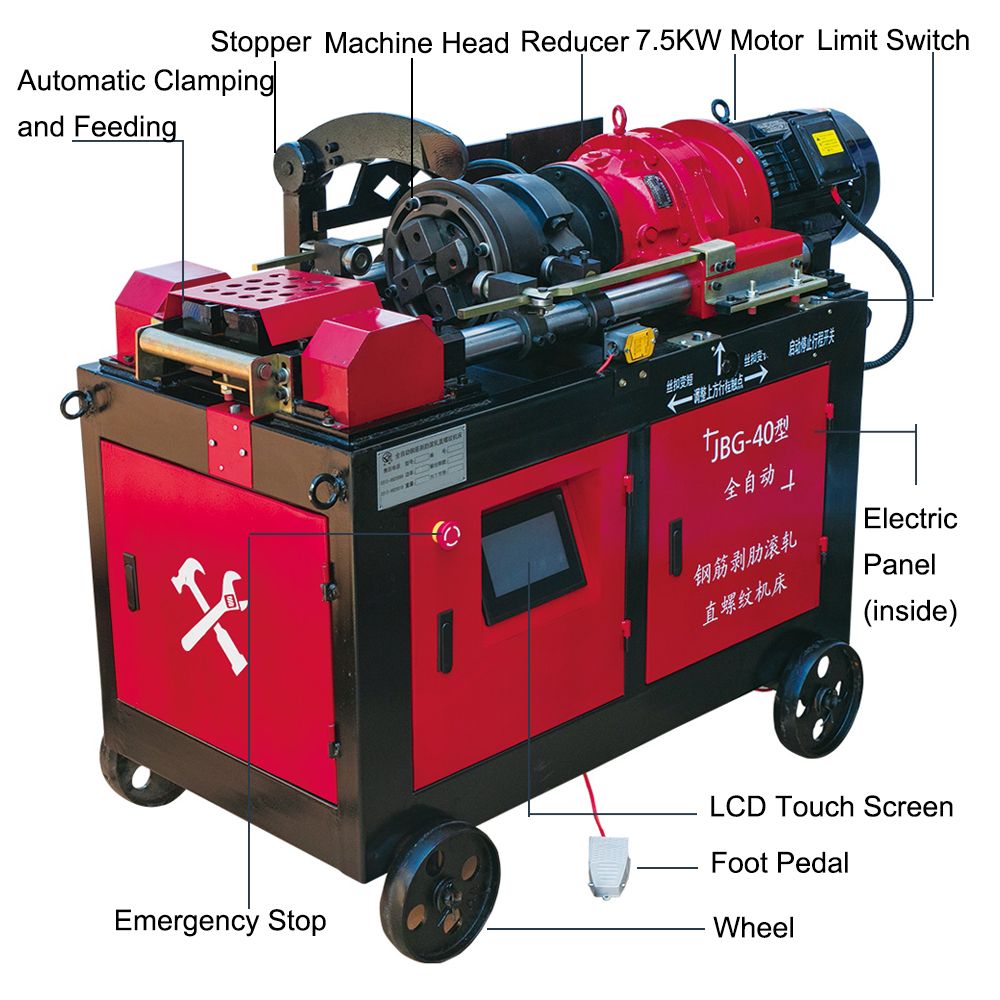

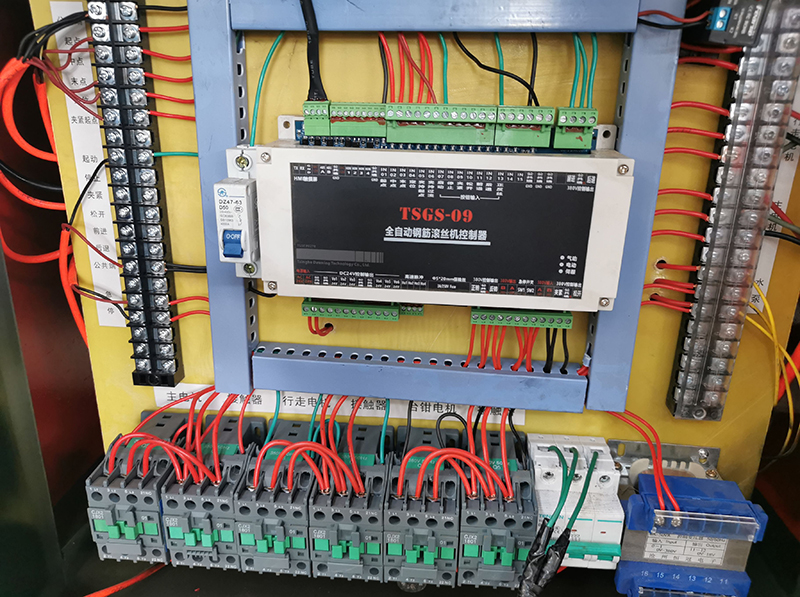

JBG-40 fully-automatic rib stripping and parallel thread rolling machine adopts new MCU as the core control unit,it has strong anti-interference performance.Controller is connected with LCD touch screen, all debugging functions can be implemented on the LCD touch screen, After the machine enters the automatic working state, the display screen shows the working status of each stage of the machine. Machine electrical failure can also be directly reflected on the touch screen, so troubleshooting is easier and more convenient.

Model:JBG-40 Fully automatic

Rebar Diameter:16-40mm

Voltage:3-380v 50hz

Motor Power:7.5kw

Max Thread Length:100mm

Color:red

Weight:450KG

Product details:

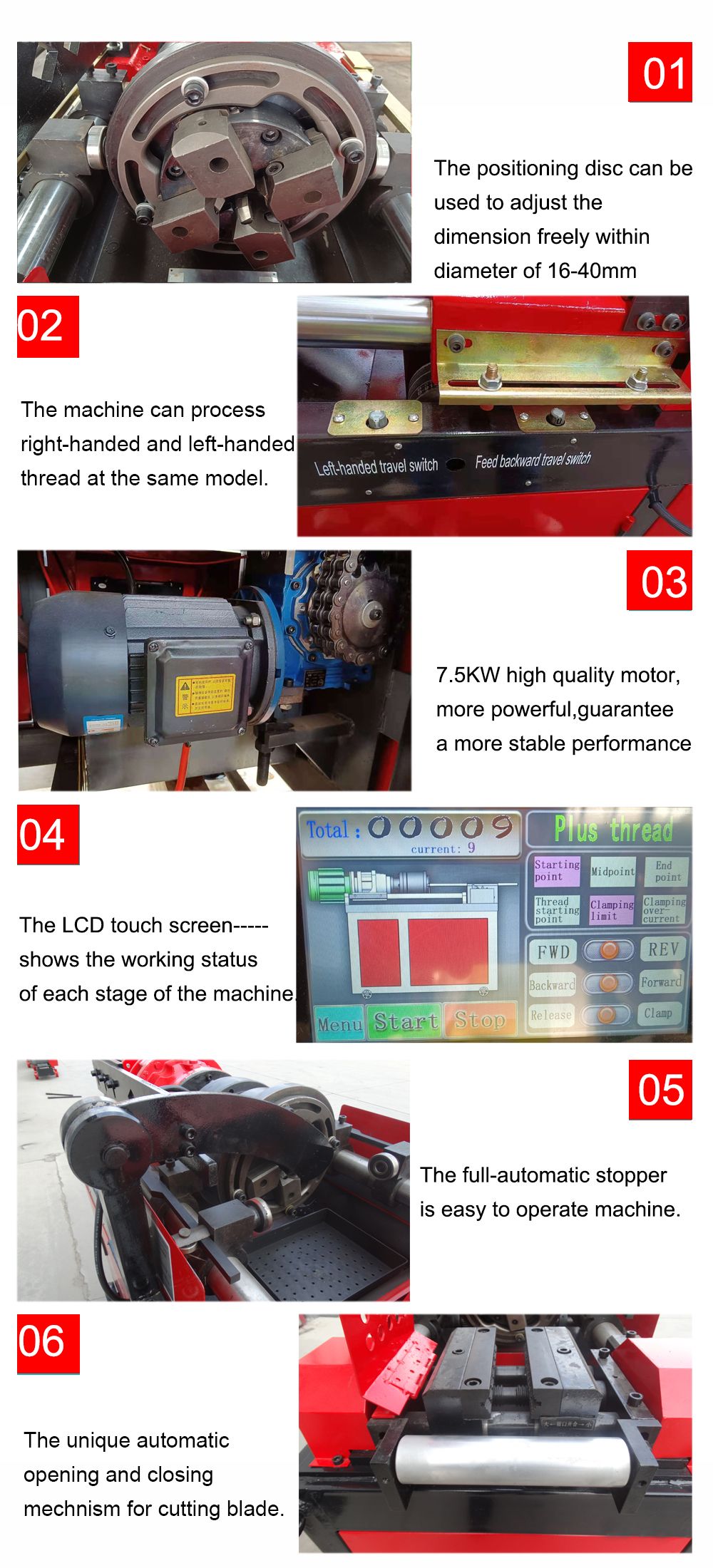

1.The positioning disc can be used to adjust the dimension freely within diameter of 16-40mm.

2.The machine can process right-handed and left-handed thread at the same model.

3.7.5KW high quality motor, more powerful, guarantee.

4.The LCD touch screen—–shows the working status of each stage of the machine.

5.The fully-automatic stopper is easy to operate machine.

6.The unique automatic opening and closing mechnism for cutting blade.

Package and Shipping:

1.Prepare the wooden pallet, place the machine on the wooden pallet.

2.Fix the cymbals to the wooden pallet with iron wire and steel nails.

3.Use plastic bags for internal packaging to prevent the machine from rusting due to rain or moisture.

4.Fasten the wooden box to the wooden pallet and nail it with steel nails at the bottom.

5.Secure with iron straps.

6.Transportation after loading.

FAQ:

1.What are the consumable spare parts? Answer: roller, blade, eccentric shaft.

2. What is the motor voltage?

Answer: machine standard motor is 3-380V-50HZ. we also can make motor of 3-440V, 220V, etc.

3. What is the thread specification?

Answer: roller specification is metric, UNC, or BSW.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for China OEM Thread Rolling Machine Roller Installation - electric fully automatic rebar thread rolling – Jindi , The product will supply to all over the world, such as: Iran, Burundi, Mumbai, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.